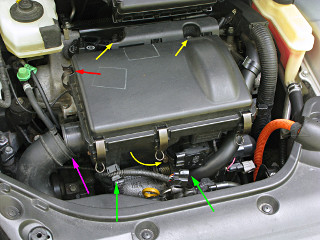

If you still have your intake snorkel [pink arrow], loosen the ring clamp bolt and slide the hose off the airbox flange. I don't even know where my clamp is anymore because that whole snorkel assembly has been OUT of my car for about five years now and I had to go find it just for the picture.

Remove the two top 10mm bolts [yellow arrows]. The bolt underneath [curved yellow arrow] loosens another band clamp around the bottom neck of the air box. Now the whole airbox unit just lifts up off the throttle body flange. Note the construction of the collar that connects the two -- the hose clamp is specific to this application, and has a little alignment hole matching a right-angle tit on the rubber collar. Now would be a good time to clean and lubricate the hose clamp screw, because it tends to become corroded and stiff.

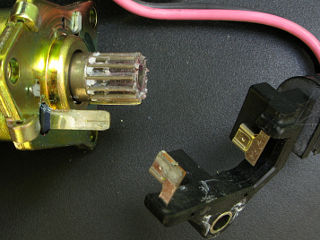

Might be a convenient time to clean the MAF, too!