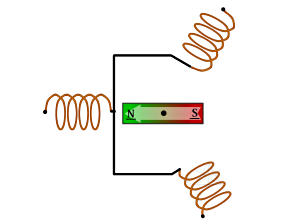

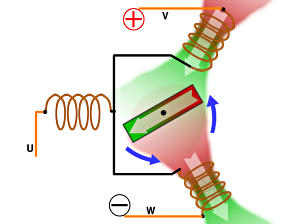

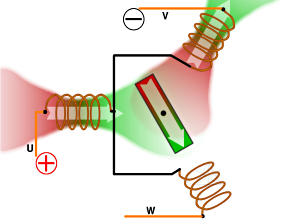

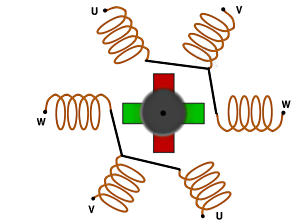

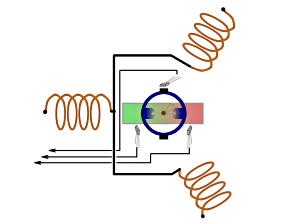

Rudimentary motor layout

Three wire coils

Bar magnet spinning on a pivot

Think "school science fair"

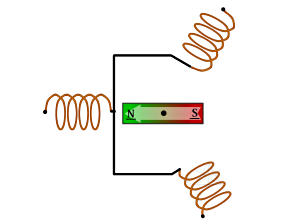

Energize one coil

Current creates magnetic field

Field aligns along coil axis

What happens to the magnet?

Opposite poles attract

Similar poles repel

Turning force exerted on magnet

Common center is internal only

So we don't really have access to it

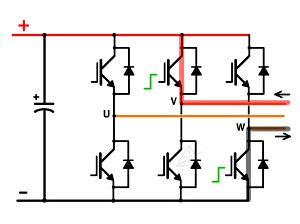

Attach the orange wires

Different labeling schemes:

U/V/W ; A/B/C ; ...

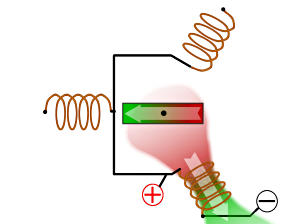

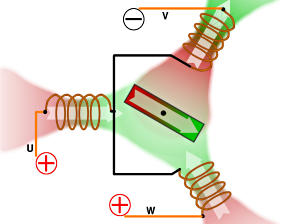

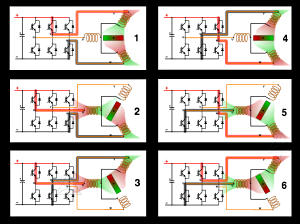

Now we energize two coils at once

Doubles force w/ same current

Now, the V coil is useless

Still have contribution from the W coil

But V coil wants to hold the red back

What do we do now?

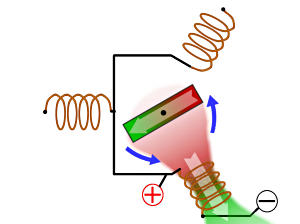

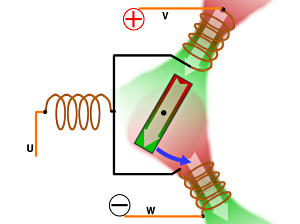

Answer: switch coils

Move (+) from V to U

New field builds from new direction

More torque to keep going

W field contribution weakens

Need to switch again soon...

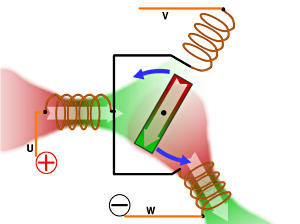

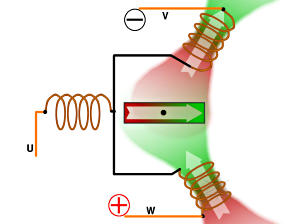

Now, move (-) to V

Maintains rotating field, high torque

Always about 90 degrees to magnet

If we're on sinewave line power instead ...

Currents build fields smoothly

All three coils carry current, except at zero-crossing

Currents into and out of motor add up to zero

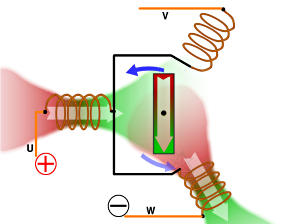

Alternate switching scheme

Fire all three coils when appropriate

Current splits equally through U and W

Two half-strength north/green fields for a while

Exact opposite of where we started

V and W now reversed

U is about to swing (-)

Waveform options

Commercial power is already AC

Switching method can "fake" a sinewave

Close enough to work well, anyway

Magnetic field still rotates

How do we get all that from a DC battery?

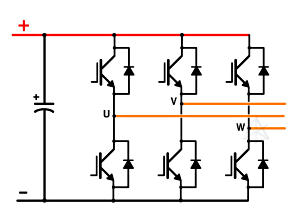

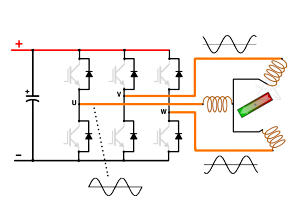

Common 3-phase inverter circuit

This shows up everywhere in hybrids and EVs

And even a few conventional vehicles now

Turns DC into AC for motor drive

Controller turns on transistor bases

Six switching states

[Read down, not across!]

One changed connection per transition

To reverse, just swap any two leads

(or reverse commutation steps backward from step 4)

Motor controllers do this easily

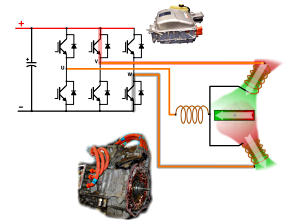

Modeling the car parts

Take away the transistors...

It all works in reverse, too

Spin the magnet, generate currents

Typical 3-phase rectifying bridge

Almost every alternator contains this

Unregulated generating capability

No controllable field winding here

Magnets don't turn off

Don't dinghy-tow the car!

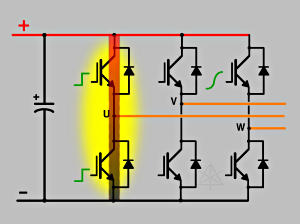

Switching both legs releases magic smoke

Need protective driver circuitry

Most inverters guard against this in hardware

Provision for minimum "dead time"

Halfway-on states are bad too

But what about sinewave drive?

How do we regulate motor power?

A method for current control

Resistors get HOT, right?

Transistors act like resistors if driven linearly

Partially on --> high voltage, high current, poof

All-on or all-off is more efficient

Off: no current --> low wattage

On: no (or little) voltage --> low wattage

On-time ratio yields average current

Switching rate is fast -- 10 or 20 KHz or more

Winding inductance smooths out pulses

Diodes smooth out turn-off spikes

Spike current sent into rails, helps charge cap back up

Helps avoid transistor breakdown

Variable duty cycle "fakes" a better sinewave

More poles for more torque, smoothness

Like two of our original motors in one housing

4 poles: 2 electrical revolutions / revolution

Coils could be series or parallel

Real-life cars ...

Insight: 12 poles, 6 r/r

Prius: 8 poles, 4 r/r

Civic: ??? Let's figure it out from RPM

Real-life motors are more "closed"

Few stray external magnetic fields

aka, "Where the heck are we"

No more mechanical brushes

We likely need some position feedback

Simple Hall-effect or inductive sensors

Small magnets attached to rotor shaft

Outputs trigger drive electronics

Frequently used in smaller motors, fans

And the Insight IMA ...

Reluctance-driven quadrature sensor

Tamagawa-Seiki "singlsyn" type

Two outputs change relative amplitude and phase

Faster and finer feedback than Hall switches

Used in the Prius

Referred to as the "resolver"

This explains the 6-wire position-sensor connectors

Driver/translator chips built into hybrid ECU

Completes feedback loop for electric drive

Armed with all this, class may continue...