Mike Dabrowski got the idea of hosting a hybrid-car owner/enthusiast gathering at his place in Connecticut, and posted a proposal into one of the forums. I figured I could combine a couple of things I wanted to do and go down a day early to help set up, and also take care of a little maintenance on a very interesting car.

[Images are linked to larger copies, as usual.]

We met Jesse at Hybridfest, and his story got written up shortly thereafter. He has taken his '02 Prius to all kinds of places, and usually pushes the car pretty hard in the process. When I heard that he hadn't changed the transaxle fluid since taking ownership around 80K miles I was well and truly horrified, especially after the frequent discussions over in the Prius techie group about used-oil analysis and service intervals and different replacement fluid options. I had changed and sent in my own transaxle fluid in for analysis around 52K. My first thought was of the one or two Classic Priuses that have turned up with shorted/burnt motor windings, and we've really been wondering if old fluid might have something to do with that. Well, to help keep Jesse going on his record-setting run on vehicle longevity, I offered to change his fluid and upgrade him to the WS type at the same time. We agreed that Mike's would be a good place to do it.

He had 309K on the car just a month previous at Hybridfest, and has put another 7000 miles under his wheels in the meantime. [The MIL is only on here because the car wasn't in READY mode for the picture.] "Just as strong as ever," he says, and emphasizes the point that all this travel is on the *original* hybrid battery in this Prius which has probably never had the re-seal TSB done on it either. By now it's impossible to get that TSB done, since Toyota moved to a policy of simply replacing the entire packs to fulfill it. And that wouldn't let Jesse continue proving his point about the original battery.

We brought the car into Mike's garage over his service pit, and I got down underneath to have a look. Jesse mentioned that he had run over something unidentified while screaming down a hill in Canada, and apparently here's the evidence -- some pretty deep scrapes on the transaxle pan which dinged the drain bolt pretty hard too. I had to gently chisel a couple of metal burrs off the edges of the plug before I could get a socket onto it. Here we see a little bit of fluid seepage around the rear edge, too, which is just one more reason to get the pan off and replace its gasket.

Old fluid drained, and pan removed. There was no inward hiss of air when I loosened the fill/level-check plug above it, so it was clearly not sealed. A fluid sample was collected during mid-drainout. I also reached into the lower extent of the case just to the left of the pan as far as I could and tried to slosh more of the old fluid out with my fingers.

Old fluid vs. new fluid. One word: yuck. Strong paraffin smell, of course, and not even a hint of pink left anymore.

In addition to the expected ferrous material stuck to the pan magnet, we also found a lot of this weird pale-tan fragmentary stuff. It has structure, and looks like it may have come from pieces of squeezed-out sealant bead from inside the case when it was put together. But it's not pliable like silicone gasket material; it's fairly hard and brittle, and more or less crushes to powder in plier jaws. We couldn't tell if it was some sort of motor-wiring insulation stuff that had broken away or just sealant that had become hardened by exposure to the transmission fluid. This and the ferrous gunk on the magnet are all going off for analysis along with the fluid itself.

The magnet, cleaned up. It just sits stuck onto the bottom of the pan. This one isn't very strong either, similar to the plug magnet from my '04 transaxle.

Another view of the scrapes and denting the pan and plug took when Jesse hit the unnamed object.

He got very lucky here. Some of the dents *almost* went through the metal, making the inside look like the steel door in those adventure movies that the monster is starting to beat its way through while our heroes try to make their escape. The rim of the pan seems to have been spared and still looks decently straight, but may not be mating quite 100% perfectly with the case. The seating plane of the plug seems to have remained fortunately flat as well. Safest would be to order a new pan, but not strictly necessary at this point. An equivalent hit on an '04+ transaxle would have probably penetrated the thin alloy casing since there's no steel pan there and nothing else in the way. Someone *really* needs to design and sell a strong but lightweight skid plate for those cars. It would probably even help with airflow.

Only a little crud in the pump pickup screen; left alone and reinstalled.

New vs. old gaskets, and a new crush-washer for the drain. Once the drain plug was out I cleaned up its edges a little more and then swapped the fill and drain plugs so the un-mangled one would be in the more critical location.

Pan back on, and in theory ready to fill.

Jesse did most of the refill, slowly pouring in a quart at a time while I stayed underneath checking for leaks. As opposed to the "hard way" refill I did on mine by moving the inverter, I've now got the funnel generously extended with a piece of PVC tubing.

The new lifeblood flows in. The entire tubing path is downhill, even though the end has to hook around the front of the transmission.

After four out of a theoretical 4.9 quarts, time for a level check. This is the correct tool for the job. Left hand is easier than right because of the shape of the surrounding case.

At 4 quarts in I could reach the fluid surface by dipping my finger fairly far down inside, and figured about another half quart would do it. I was right; the extra half quart brought it *just* up to the hole edge and sent a tiny dribble over it. So that means there's still a little bit of the old fluid mixed up with the new, but we're figuring on another change maybe around 350 or 360K which will act as sort of a flush.

While I was under there, I noticed that his blockoff plate is on *correctly*! Is it like that on all Classics, and somehow the factory-floor assembly instructions got screwed up between '03 and '04 production??

I buttoned everything up and we took a test drive; in fact the first time I've driven a Classic more than a couple of yards. Everything seemed tight; a tiny bit of weepage near that same back edge of the pan at first was probably just from the cork gasket compressing and has since stopped. So, done for now! Some other nominal checks were performed. I could not get my AutoEnginuity scantool to talk to his battery ECU and show me block voltages, which would have been useful to collect. All the emissions monitors pass. The throttle body doesn't look too bad but could probably use a swab-out at some point. The water pump pulley has an interesting bend to it, causing the shiny belt wear area to wobble slightly across the surface; I think the next shopping trip is going to be for a water pump since there's definitely some bearing play starting in the existing one. But hey, over 300K on what's probably the original water pump is pretty impressive by itself. What's slightly more worrisome is a cracked weld around the rear seam of the HCAC catalyst that's generating a small exhaust leak -- fortunately after all the O2 sensors and first catalysts, so not affecting emissions monitors but should probably be checked if it's leaking hydrocarbons on a cold-start. Brake fluid and coolants are likely to be relatively recent since he's had work done on both systems over the two-hundreds as needed. We'll try to get his complete maintenance history on record somewhere.

|

|

While the Saturday of the maintenance work was quite hot and I was sticky and sweating onto everything, Sunday was cooler and cloudier with a certain chance of showers. Mike and I set up our canopies over what we thought would be the best hang-out space. Nonetheless, we got a pretty good showing of folks and cars! There were a couple of little spits of rain here and there but for the most part the day remained dry. I didn't get too many pictures and only thought to start doing so when a couple of people began to leave. Check the forum thread linked above and see if anyone else posted more pictures.

|

|

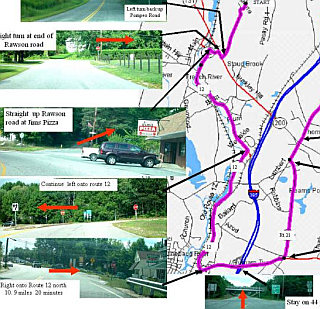

While folks hung out and talked under the watchful gaze of Sparkie the Robot and/or got the grand tour of Mike's place, some of us took test runs around the loop that we had worked out earlier that morning. Mike had the very useful idea of generating a map off the GPS software and then dropping in pictures of critical intersections and which way to go at each one, so that drivers could know if they were still on course or not. Brian and I drove the 17-mile loop that morning, taking pictures and notes [and getting breakfast!] while Mike was back cleaning up the shop, and then we assembled the whole thing to print nice and large on 11x17 paper for anyone who wanted to take the run. Nobody really seemed up for doing an official MPG competition, but we used the route for test-drives and a clinic or two and noted that this may be a nice way to document routes in future events and help drivers not get lost.

Pastries and iced coffee and demo-pieces, all mixed up on the table together. The plywood is actually my freight bed. Which had to go back into my car before anything else could when it came time for me to pack up!