| Late spring went by in a bit of a whirlwind, some of it spent on planning for events later in the summer. This year's roadtrip would take me to Texas, where the lighting rig I was tasked to design would get built and flown. With quite a few items crossed off the house to-do list by now, the ongoing retrofit follow-up work could take a bit more of back seat. |

Light and heat

|

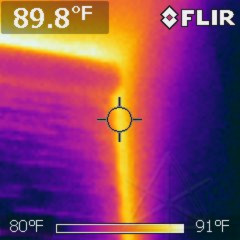

But things were heating up! The window shades in back were doing

a great job helping block whatever dribble of radiation managed to get in

through the low-SHGC glass, but still giving rise to convective loops in

the inverse direction from winter. Again, not in a way that seemed

to be spilling lots of hot air up out of the window boxes.

I remembered the idea for a small mid-level awning rooflet along the back wall over the first-story windows that the builder had talked about at one point, and felt reassured here that it would have been extra trouble for very little gain. |

|

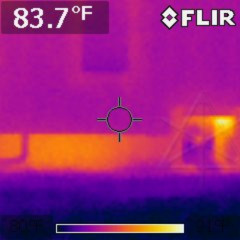

For the most part the foundation remained its somewhat inscrutable self from an infrared-scan standpoint, but this time the boundary of where the additional insulation to date stopped was fairly well-defined. After a day's worth of warming on the back wall the blocks were clearly storing some of it, but the ones toward the left where the added insulation was evidently weren't getting quite as cooled down by conduction to the cooler basement. The wall temp closer to the condenser hutch seemed to drop off across a fairly clear vertical line corresponding to where the new foam ended. |

|

So I really wanted to get the basement job completed. I only needed three

more 4x8 sheets or a small batch of cutoffs or seconds, and wasn't too fussy

about what form factor it might come in as long as it was still foil-face.

After a couple of fruitless excursions around Craigslist and

Insulation Depot wound up

inquiring at the local lumberyard, the same place that had given me the

beat-up blue board. They stocked 2" polyiso and would even deliver

a small amount across town for free, so I went ahead and ordered.

To clarify, I wasn't even close to needing any cooling yet so the whole HVAC system remained shut down for much of this time. The basement humidity kept drifting up a little, though, which I kept in check with occasional runs of the dehumidifier. [Not the hacked-up air conditioner anymore, I had trash-picked a "real" and better-optimized unit from around the neighborhood that still worked fine and only needed a bit of cleaning.] This is the shoulder-season problem: the air outside isn't overly hot but carries a lot more humidity, and we don't necessarily want to just throw the house open to that. Judicious ventilation and dehumidification of what comes in, without necessarily cooling too much, is what's needed and unfortunately that still requires throwing a little energy at the problem. Still, with the time-of-use billing in effect my June electric bill was possibly the lowest I'd ever seen. |

|

A few days later the truck from the lumberyard arrived on a rainy morning, with my meager three panels shrinkwrapped up into a neat package that was easy to zip into the basement. |

The last bits of basement wall

|

It was also rather fiddly to get the layer completed behind the water

heater, which I wasn't about to empty and move just for this. I had

already added some pieces directly behind it a while ago, extra foil-face

to try and reflect some of the radiation coming off the warm

fittings on top. Using up all kinds of random scraps in a truly cut-n-cobble

fashion I eventually worked around the soil pipe and the washer drain riser

which itself annoyingly sat less than two inches out from the first

layer ... but whatever, it didn't have to be perfect, just better and

more air-sealed than the old stuff.

With a large feeling of satisfaction I cut the two long strips of 1"

needed to close it all up around to the doorframe [leaving a gap for the

compression bar hook] and let them cure into place before taping. Said

gap got a couple of filler bits stuffed in behind and all sealed up too,

and the last of the visible cinderblock -- except for my deliberate

test hole -- was GONE.

Except that we had gotten well into warm weather, so I wouldn't be able to tell if all this would have any real effect for another several months. |

Condensation management

Water and fire

|

One of the long-running local activities was the progress of a new

subdivision development across the way, part of which was going to

involve upgrading my street. We actually fought this project for

over fifteen years in various town halls, because the local residents

knew that a plan that straddles a town boundary is just a stupid idea.

But the developer just wouldn't give up, and finally got his go-ahead

on it and the related

road improvements

so having the street in front

of my house ripped up seemed inevitable. It remained to be seen if

having the subdivision go in was going to be a benefit or a detriment

to the neighborhood long-term, and it did enter my thinking a little

while planning the retrofit. If nothing else I had probably given a good

resale-value boost to my place regardless of what would happen to general

neighborhood values later, not that I really had any intention of

leaving it anytime soon.

As part of various proactive thinking I figured it might be a good idea to re-identify my water shutoff, which I had lost track of since the last time it was dug up. Quite a few years ago I'd had a leak right at the curb-stop valve itself and it had to be replaced -- and being five feet underground, it was a rather interesting operation done long before I owned a decent camera or there would be a page all about that too. At that point I had gotten a pretty clear idea where the top of the valve casing was, but failed to mark it with anything and as leaves fell on the area and snowplows deposited more crap on top I realized I didn't really know anymore. But I wanted to know, not only because it's a good idea to have detailed information about your immediate infrastructure but because part of the subdivision-related plan would involve extensive excavation to put in new drainage infrastructure under the roadbed. I had no confidence in the developer's ability to not screw something up in the process. Besides, it could be an opportunity to get the valve cover up closer to the surface if the digging was going to intersect where it was. So I dug around where I thought it had been, played with a couple of small metal detectors whose range was piteously inadequate, and eventually gave up and asked the town public-works department if they had any as-builts I could get measurements from. |

|

They didn't have any drawings, but they were happy to send out a guy with the Big Beeping Wand to help me out. Took about two minutes to nail it. |

|

Which was kind of amazing, actually, because it had subsided quite a bit

farther down than their usual depth. Apparently the telescoping valve

casing tubes tend to slowly sink over multiple freeze/thaw cycles, so since

the previous exposure it had been steadily vanishing down into soil that was

probably softer after the excavation anyway. But here it finally was

in the light of day again, so I grabbed measurements relative to the

house wall and as I filled it back in, did my usual trick of placing a

couple of bricks on top with their ends sitting just at the surface so

finding the exact spot would be much easier next time without having

to leave the silly little blue flag over it. Apparently kids swiping

those is a common problem anyway.

Wouldn't having a larger flange on the top section of the valve chamber help prevent the tube subsidence?? Seemed like a no-brainer. Well, it didn't really matter as all of this got a real fix during the road paving job. |

|

In the meantime, back to water. A bit of a heat wave was going on

by then with daytime temps pushing 100, but the house didn't seem to be

warming up a whole lot or at least doing so very slowly. The high-SRI

roof was really doing its job again! Outdoors had nonetheless gotten

pretty disgustingly humid, and I was trying to keep the place closed up

and ventilate as little as possible to avoid bringing the yuck in.

It finally became time to kick the

main system into cooling mode, and part of that included finishing the

wiring from the condensate pump to the integration box to enable

the overflow switch. This at least didn't need fancy relays, being

just a simple dry closure to the "forced off" input at the air handler.

Eventually it got warm enough inside to be worth actually cooling, when the main system would handle the incoming air and I could test the overflow safety. There was a perceptible difference in compressor load between letting the system control the HRV or keeping it off, because running the HRV on humid days brought in a significant increase in latent load. But at the expenditure of a little more energy, at least nicely *dried* outdoor air would get exchanged into the house. |

|

So yay, the cooling was finally ready to be on full autopilot. The

air-handler would control the HRV so any incoming ventilation would get

conditioned first, and a two-event schedule programmed into the controller

would simply keep the system off during the electricity peak-rate times

and bring it back on in the evening. I gave it a setpoint of 78, figuring

that would be enough to invoke a little cooling but not go nuts about

it -- because I wasn't going to be there for the rest of the high summer.

It was time to put the car in "RV mode" and make that roadtrip to Texas.

Which hasn't been written up yet, but will get done at some point as it became a *very* wandering path to San Antonio that went through Glacier National Park, Yellowstone, and hundreds of miles of mountain backroads in the process. It was pretty awesome, as I've discovered is my usual perception about places out west. When I finally returned, the first thing I noticed on walking in was a strong smell of polyiso foam. Which was a symptom that very little ventilation had gone on. I checked the HVAC meter and found that the total power demand over the time I had been gone averaged out to the 2 kwh/day compressor standby -- the system had *never run* to cool the house the entire time I was gone. Granted, there weren't a whole lot of cooling degree-days for that month but even with a setpoint of 78 I figured there might have been a couple of peak days that could sneak the house up to that. Apparently not. Have I mentioned the nice heat-bouncing SRI of the roofing yet?? And the humidity basically hadn't changed at all either; lack of exchange and the tightness of the envelope meant none of the outside air had managed to get in or even diffuse its moisture inward. |

|

I could also get in along the inner edge of the pan through my nifty new access hatch, and brought in a hose nozzle to try and spray down into the pan to float loose any of the guk that would. This was of dubious productivity, as it may have accomplished little besides getting me wet. But while in there I recalled that parts of the coil fins weren't in perfect alignment as it had come from the factory. A quick trip to the local HVAC house later I came home with a fin comb kit, and used it to straighten out a few slightly mashed areas. The silly handle that came with the comb is pretty useless for confined spaces like this, and it was easier to just hold the head piece and carefully run the part with the correct spacing down the fins. |

|

Okay, so summer performance seemed to be really excellent overall. The

only minor downside was the fact that the supply registers didn't kick

cooled air all that high into the rooms, so it tended to hug the floor.

It was simple enough to stand angled-up pieces of cardboard in front

of some grilles to help push the output higher up, and interior humidity

extraction wasn't going to be affected either way.

But in our heating-dominated climate zone, I was already thinking ahead to winter! That whole snow guard kit was still sitting in boxes, and it was time to work toward installing it. |

Think snow

|

Same thing at the other end the same distance up and a nice tight stretch of the string between them, and I had a nice reference line along which to mark for placement of the rest of the clamps. |

|

Each seam needed a little squeeze before the clamp would fit over it, as the clamp openings have a slight inward lip at the edge. There's tape on the duckbill jaws for good reason... |

|

Next step was to preload the parts onto the rail extrusions, alternating the hold-down clips with the panel feet, and haul all that topside. |

On display, against the odds

|

Winter was still a ways off; the leaves hadn't even really started to

change yet. I had another few things to take care of before then, and

the next effort to put in quality time in on was an opportunity to

show all this off a little, other than on an obscure website.

It was time for *me* to take my turn at hosting a Green Buildings Open House site, seeing as how I'd managed and done and documented all this work and had developed a healthy enthusiasm for the field. I went to look more seriously into the guidelines for hosts on the NESEA site, and was a little disappointed to find that they were apparently giving up on doing the level of publicity they had enthusiastically spearheaded in the past [as well as ignoring my suggestion that they should try to make it a two-day weekend event to allow for more site visits]. It was hard to tell if that stemmed from a lack of funding, time, personnel, all of the above or some other reason. Maybe trying to piggyback onto a "solar tour" that was less about building improvements per se wasn't working out for them. The main GBOH page now seemed to consist of a bunch of excuses basically saying "it was fun and we learned things but we're tired and can't do this anymore", and encouraging site owners to do their own local publicity if they wanted to host. Fair enough on one hand -- distribution of labor. But reading that cemented the impression I already had that this was probably my only chance to participate in GBOH as such at all, because it appeared to be a dying effort and would probably peter out entirely in the next year or two. NESEA had already outsourced handling the site list to a third-party outfit called EnergySage, a website with a fairly awful design where building owners would sign up and then create "projects" to profile their properties. [Another goddamn password to remember...] At least they were still providing host kits with lawn signs and copies of their trade mag, but weren't shipping them anymore so I picked a day to haul out to Greenfield and pick up a packet. I hadn't seen their offices since back in the Tour de Sol days and wanted to see how things had changed. It was a completely different crew from the old guard I had gotten to know back then, and it didn't feel like longterm institutional memory was particularly high on their priority list. While on the road I also stopped by EcoBuilding Bargains in Springfield for a look around, which was fun -- it's like the Habitat ReStores, but bigger and better organized. Nonetheless, for GBOH I set to and did my part -- signed up at Energysage, worked through entering various aspects of my project with some rough cost-savings analysis, and tried to reach out to a few of the local press contacts in the sadly out of date NESEA database. I even took and reworked the bad iphone-snapshot-grade picture of said lawn signs from the website, and supplied them with an improved graphic to replace it for the benefit of those who might want to print their own. I could rant on further about NESEA's former glory and how petroleum fuels need to be up around ten bucks a gallon-equivalent before anybody's going to actually sit up and take notice, but you probably get the idea. |

|

Since the whole idea of these tours was to point out energy-related features of a given site, I had the idea to print up a bunch of little informative labels and paste them all over the place to make it like a little self-guiding museum. [Is that what they call "interactive displays" these days? What an idiotic term..] In a way it was just like printing up a bunch of technical details on the Prius and tooling off to the car and energy shows like I'd done a few years back, which was how I hooked up with NESEA and the last gasps of Tour de Sol in the first place. I went back through my notes for content ideas and wrote it all up, wrapping a bit of Postscript around it to facilitate print formatting, and then picked a distinguising color of paper for the output. An HTMLized copy of all the sign text is here for the curious, which among other things is a nice capsule summary of all the stuff I'd done on the house. |

|

While the event wasn't a total bust for me, attendance was pretty sparse.

Four or five couples or small groups came by over the course of the

whole day, including an engineering type fellow I already knew

who I'd met at the previous

year's event, and some lady who was confused and just looking for

realtor open-houses. In other words, not even a whole lot of choir to

preach to, let alone hordes of the general public. But it was kind of

fun to pass good information along to a few folks who seemed genuinely

interested, so in a way it was a very minor success and I lived off

the largely-untouched food supply for the next week.

It also taught me that setting up enough signage to guide people to a specific place in a neighborhood is an interesting bit of work, which of course includes the recovery and cleanup afterward. Sightlines require careful consideration, as do property boundaries, and signs ideally should be bigger and higher off the ground than they look when approaching them in a car or they visually vanish. |

| With GBOH out of the way and likely forevermore, I eagerly anticipated the coming winter. I had a better-suited basement now, snow management for the back roof, and more ideas for various testing and stats-collection to do. Disney's lighthearted animated tale "Frozen" had just been released, and I could totally identify with the appeal of constructing one's own thermally-preferable domicile in the frigid northern wastelands. I'm not sure Elsa's ice palace would have features like functional indoor plumbing, but let's not wreck the fantasy -- like the song says, let it go. |

_H* 140423