|

As driver attitudes on the roads have continued to degenerate across the

land, being able to control vehicle spacing in the rearward direction has

become even more essential.

I described the original

Yuppie Button and the motivation behind

it as it was installed in the Prius, and with a decade-plus of experience

behind that one I now view it as a mandatory safety feature for any car

I own.

I clearly needed the equivalent in the Kona basically the minute I pulled out

of the dealer lot, so getting one designed and put in was a high priority.

Unfortunately, it isn't feasible to design a universal "yuppie button kit" for any car. Every vehicle's wiring system is different enough that it has to be a custom job, built with intimate knowledge of its base wiring. The technology of how automotive lights are switched and driven, and even the lighting units themselves, keeps changing, so the right way to work with all that has to adapt as well. |

|

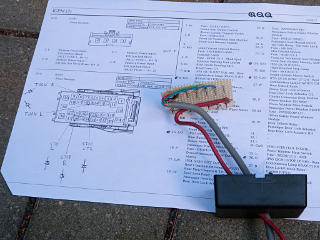

The diode box got tucked up behind another module next to the firewall, tied up with a bit of trickline and stabilized with tape later. Almost completely out of sight, and it almost looks like an original part of the car except for the stray bits of gaff tape. There's actually a ton of room under the dash in general, with things not quite as crammed in under here as with the Prius. |

|

That box whose bracket I used as a support is interesting in its own

right.

It is the Charge Control Module, which only comes into play during

high-speed DC charging.

Even though it's completely out of harm's way under the dash here,

it has a big fancy weatherproofed connector, and appears designed for

under-hood mounting instead.

The parts-location picture for it is also a very different style than

the other photos in the same section.

This strongly implies that an original design called for it to be under

the hood near the charge port, but got moved here later using the same

hardware.

Perhaps other car models have the same thing under-hood, dunno.

What having the CCM's harness here does provide is an accessible tap of the charge-port pilot line, which is otherwise buried in heavily weatherproofed harnesses running straight from the charge port to the on-board charger. I would certainly want to watch this line during DC fast charging, because it's where all the magic happens as far as communication between the charger and the car. So while working under here I added a short tap wire to the pilot line [pink arrows], which in the CCM's harness is the white wire. It could just hang here quite safely, and would be easy to hook a scope probe onto. The separate charge-control module and evident indecision over where to mount it isn't the only thing that makes me think that fast-charging capability may have been kind of a last-minute add-on to the Kona design. I discuss that more in the rapid DC section, where I finally get around to testing that. | |

_H* 191014