Electrical analysis begins

Now that all these parts have been removed from the inverter unit, we can

start playing with them a bit and explore their electrical/electronic

characteristics. This leads to a deeper understanding of the power

engineering that went into this and current best practice in the field --

possibly to the point of being able to re-use this unit either in another

Prius or as a component of some completely different project. I've spoken

with a couple of colleagues about some fairly scary "Frankenprius" ideas...

Boost coil

There's not much to the boost inductor. Well, except its ability to store

and release energy! This is a time-shot of quickly brushing past one of its

terminals with a lead from a battery [a Prius module, appropriately enough]

whose other terminal is held on the other coil terminal, and the high-voltage

"pow" and bits of flying molten metal from that single pulse are pretty

impressive. Now, consider that those IGBTs inside the boost switch do this

12,000 times per second and usefully capture all the results! [That figure

is real, from watching the CPWM converter-drive lead from the car's ECU.]

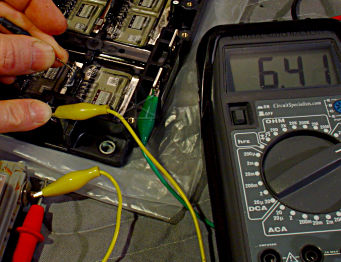

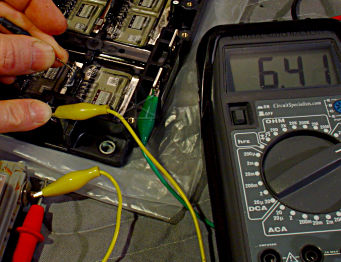

Power transistors

How about those big power transistors? What are their characteristics?

With gates that massive, how much charge does it take to turn them on?

Here we won't get a quantitative idea of that, but a little playing around

can give some idea. The Prius battery module is hooked up to emitter and

collector through a dropping resistor to limit current to about an amp, and

we read the voltage across the transistor. With it off, I see full battery

voltage. [Which, by the way, is normal real-life for a 6-cell Prius module

even though it's rated at 7.2V]

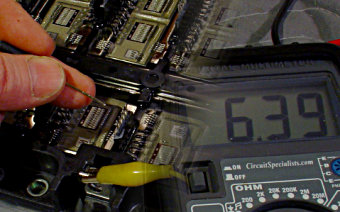

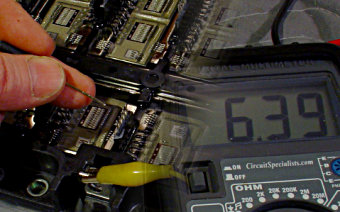

Using a pin-probe, a couple of fingers, and my body as a large resistor,

I can bleed a little charge into the gate lead and watch the voltage across

the transistor decrease as it starts going into conduction. Holding long

enough, i.e. a few seconds depending on how hard I press the metal, clearly

goes all the way into saturation, and then by shifting my other hand to the

negative lead I can drain charge and get it to turn off again. Here, though,

we've gotten a little way into the linear region...

and by removing the pin-probe to the gate, I can cause the voltage to just

freeze right where it is. It just holds there -- doesn't drift up or down

for a very long time, until the charge is given a path to dissipate by

touching the gate again. Just like a FET should, of course, and the leakage

exhibited here is small to nonexistent.

Forward voltages appear to be fairly normal -- diodes and saturated transistors

at 0.6V when non-trivial currents [~120 mA] are passed through them. The

forward voltage of the entire rack's worth of diodes, taken at the supply

inputs, reads 0.95 under the same conditions. You can guess what would happen

if this were hooked up to the 200V battery as ORNL had it labeled! Playing

with higher voltages and currents through the rack will wait until some later

phase of testing.

The devices in the boost switch are similar, although its diodes appear to

have a lower forward voltage of 0.5. Obviously, the lower the better.

Control board

The control board has its interface connector nicely documented, albeit at a

bit of distance. These connection names are the same as used at the ECU, and

described in the "Terminals of ECU" section of the service manual. This is

really useful, because it indicates how to hook it up to power and where to

find real-life signals in the running car to try and reproduce on the bench.

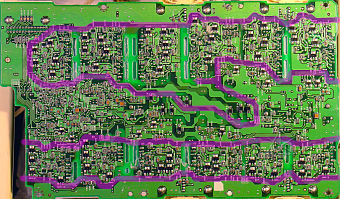

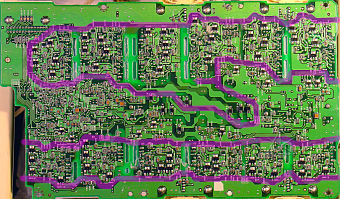

First, we need to get the best possible pictures, not only of both sides of

the board but also attempts to probe *inside* a little by shining light

through to show where the vias are and even which direction they might

roughly head. This was a quick-n-dirty rig to hold the board at the edges

and light from above or below and try to keep the camera exactly positioned

the same way. It almost worked as intended; a bit of post-correction was

definitely necessary.

|

|

|

|

Front

(front lit)

|

Front

(back lit)

|

Back

(back lit,

flipped R/L)

|

Back

(front lit,

flipped R/L)

|

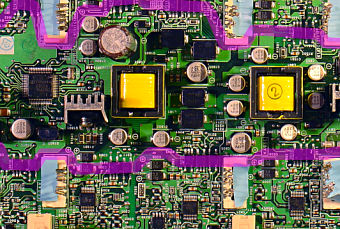

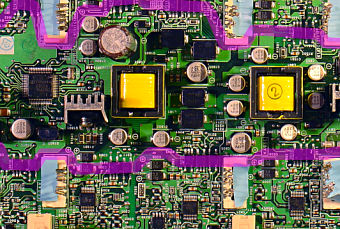

Here's a set of four large images that have been stretched around a little

bit, and the rear-view ones flipped right-to-left, such that they very closely

match up via-for-via when loaded into one's favorite image editor as layers

on top of each other. There's a lot of power-plane in there, so this may or

may not help with further circuit-tracing but is kept here for reference.

The blue tape over the gate connection slots is simply to keep light from

blasting up through them from underneath.

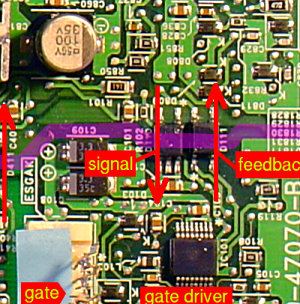

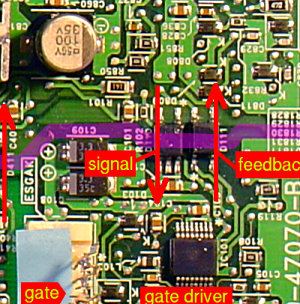

With a little more familiarity with how the thing is laid out and what to

connect to, it's time to get the *good* module on the bench and start tracing

some things. No IGBT rack connections are needed yet, this is just playing on

the 12V side and trying to figure out what eventually gets sent to the gates.

To get through the conformal coating to reach solder lands, a very sharp pin

probe is needed. It's easy to make one out of a paper clip; the plastic-coated

type provided a little more protection against randomly shorting things if,

say, it's dropped onto the board.

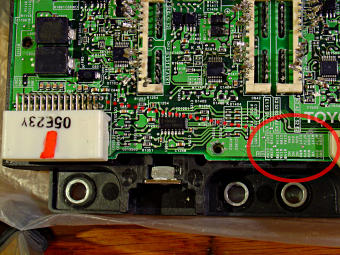

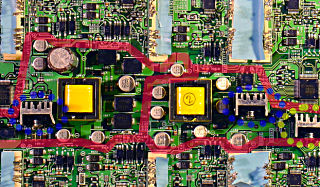

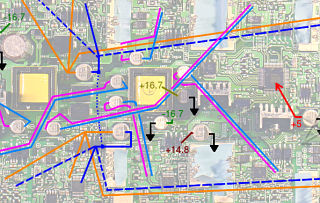

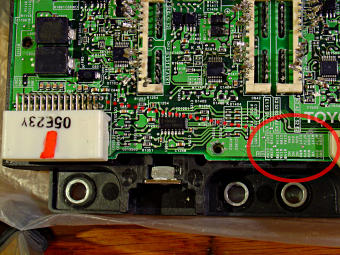

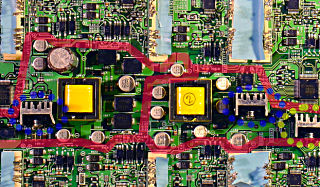

A little bit of 12V conditioning happens over at the right, and then the entire

middle section [red boundary] consists of two mostly independent power

supplies. Upon supplying 12V power to IGCT and GINV, the two yellow

transformers begin emitting a soft but audible high-frequency hash typical

of switching power supplies, and a whole bunch of voltages appear at the small

electrolytic caps scattered around them. The two heatsunk power transistors

circled by blue dots are tied to ground at the emitter and exhibit the high-

frequency [and somewhat jittery] transformer-drive waveform, and the ones

circled with yellow dots seem to be linear regulators for 5V that feeds the

two processors and some other stuff.

The board draws about 0.7A at 12.5 volts, and 0.8A at 10 -- higher draw with

less voltage, typical of a switching power supply. At 7.8 volts it draws about

an amp while trying vainly to start up. The 5V fails at 5.7 volts input,

indicating fairly low drop-out regulators. After the board has been running

for a while, the warmest components on it are the little yellow transformers.

And not inordinately so -- once again, high efficiency, minimal wasted power.

Strict isolation is maintained between the chassis-grounded 12V system and

the entire HV system including battery, motors, and transistor rack. But the

inverter is one of the places where they must come close together, so there

needs to be a bit of magic here. [The other place, of course, is in the

battery ECU for sub-pack voltage monitoring.] There are isolation barriers

down the whole length of the board, bridged by pairs of optoisolators to pass

signals in various directions, and all the power to the gate-driver circuitry

comes from isolated sources. So that's almost TWO layers of isolation if you

consider the insulated gates another barrier. Well, you can't really think

of it that way because the high-side gate driver circuitry has to operate

somewhere above the motor lead's voltage at any given time so that whole

section must float around at a fairly high voltage when running. What's not

yet clear is exactly how that's done, or [related] how the ground-fault

monitoring works.

The isolation gap is even more obvious on the backside of the board, but this

also shows how some of the floating power-supply outputs connect to the HV

side. The upper and lower edges of the board get back into non-isolated

territory, to interface directly with the current-sensors [which are yet

another isolation-barrier component!]. In this view, there are twelve fairly

distinct denser areas of circuitry near the control-lead slots -- these are

the sections that stay isolated and actually control the transistor gates.

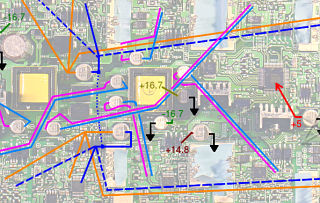

With that in mind, a couple of hours of probing around with a scope and meter

in "diode check" mode to find where things are hard-connected together has

pretty much ferreted out where all the power goes. It is soon apparent that

split (+) and (-) supplies are utilized -- they feed several analog components

including the current sensors. Those are interesting -- they appear to have

two exactly duplicate outputs, which get routed back to the interface connector

as signals like "MIVA" and "MIVB" which scope out as exact clones of each other

in the running car. Why two?? Not only that, but they swing above AND BELOW

ground, right into the hybrid ECU. That means the hybrid ECU must have some

negative-supply stuff inside it too. Why not an easy single-supply swing about

2.5V, like the main battery current sensor? A bit of a mystery there.

The really fascinating thing is how the gate driver supplies are done. Each

power supply section produces four separate 9.5V or so floating outputs, one

slightly more heavy-duty [well, at least with a larger filter cap] than the

other three. The large one [where "large" simply refers to its capacitor]

feeds all the low-side transistor drivers. The three smaller ones each

independently feed the three high-side driver sections for MG1 and MG2, which

begins to make it clearer how the high-side isolation is done. The answer

seems to be six totally separate little supplies.

In the assembled module, all the low-side supply negatives are hard-tied to

each other, the "E" control leads, and the main (-) supply from the battery.

But there's something a little funky about them -- without the transistor

rack in place, the negatives [blue] of the low-side driver supplies aren't

tied to each other [lightly dotted line] and are only hard-connected to the

driver circuitry in the "V" areas. It isn't clear how the negative supply

for "U" and "W" gets there but there's some other component in the way. But

the three positives per side are definitely tied together as shown. Again,

once this is all soldered down to the rack, it's largely irrelevant and all

rides wherever the negative of the 200V battery sends it. I can also see

that there's an extra optoisolator device from the "V" low-side back into

the nonisolated area, which is undoubtedly related somehow to why it's got

the "real negative".

Here are some of the early discoveries as to where the switching signals

go. I'm sending a simple oscillator into the "GUU" lead, which controls

current to the "U" phase of MG1, and trying to find how it eventually gets

to the IGBT gates. I've found it up to the processor, which is a dead end

until the "GSDN" gate/shutdown lead is brought high too, and then I discover

a split-out pair of complementary signals in response that eventually hop

through two of the optos and go to the gate driver chips. When GUU is low,

the lower transistor of the pair is turned on; when GUU goes high, it turns

off and the upper transistor turns on. There is NO both-off state, except

for when the overall "gate" lead goes low and then all the transistors turn

off [i.e. the definition of "neutral" in the car].

This switching works down to DC and has a little hysteresis, changing state

as the input rises above 8 volts and again as it falls below 6.8 or so. No

IGBT gate output appears until "xSDN" is brought high, and then the next

rising or falling edge at the "xyU" lead starts producing output.

In the MG2 section, each transistor gate pair is simply tied together, so

the gate driver chips are evidently amply capable of kicking both of those

monsters at once.

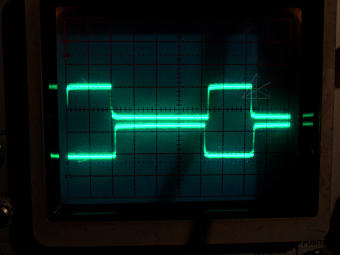

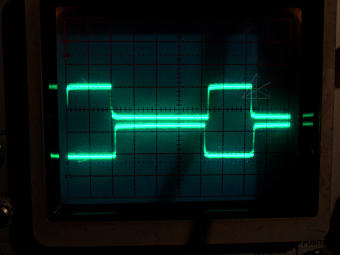

The last thing anyone wants is both elements of a half-bridge to be on at the

same time, which would cause a shoot-through short across the supply and rapid

loss of the magic smoke that makes things work. Since you can't instantly

turn on one element of a half-bridge and turn off the other and guarantee no

transition leakage, there has to be some minimal amount of guard time during

which both are solidly OFF, usually enforced in hardware. Here, by sending in

a single squarewave input and scoping the corresponding pair of gates, I've

found that time to be 6 to 8 microseconds. This appears to be done at the

processor outputs; it isn't yet clear if there's a backup system to prevent

disaster if the processor should ever wig out and turn on both outputs at once.

Given the amount of circuitry around the gates, I would expect an additional

level of protection in there someplace -- but that would mean more signals

needing to cross the isolation boundaries. Maybe that's part of the feedback

path -- remains to be seen.

For all its sophistication and apparent complexity, this device is still wholly

a slave to the hybrid ECU. It does exactly what it's told via the gates and

switching-control lead triples, and only sends a little running data back. It

has no sense of 3-phase sequencing and cannot intelligently drive the motors

for propulsion by itself.

From here, I can try to find some part numbers to help further determine

functionality, compare against what other analyses have already found, and

start getting into what someone would need to know about switching strategy

to usefully control this mess. And I still haven't even touched the cooked

DC/DC to try and figure out what the heck happened to it yet.

Next: Electrical analysis continues

Home

_H* 070604