Perky pipes

|

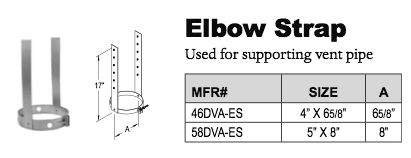

Another "make it nice" project I wanted to get done was to finalize the

HRV ducts and actually use those handy attachment blocks they'd put

into the siding. In searching around for various commercial

pipe brackets I looked at some of the offerings in the

F.W.Webb catalog

and realized that these were really so simple and obvious

that the best answer was to just build my own. Out of what, though, since

it was going to be outside? My usual knee-jerk impulse toward steel

packing-strap wasn't going to work as that wouldn't last very long.

Aluminum might not be quite robust enough and there was the immediate

question of what kind of fasteners would be suitable with that. On

the other hand, galvanized with zinc-plated hardware would be stronger

and reasonably corrosion-resistant and I had various bits of sheet steel

kicking around including some the HVAC installer had left me, so now

I had a plan.

|

|

| The next problem was what to use as rain hoods. There was no way I was going to hang a 180-degree "U" of two more heavy PVC pipe elbows on top of my risers, even though we see similar constructs sticking out of septic tanks and sealed-combustion furnaces all over the place. That's what the HVAC installer had in mind when he brought the parts, anyway, but that done in 6" pipe would be pretty monstrous. For a while I fixated on finding something with a 6-5/8" *inside* diameter as that would fit nicely over the outside of my PVC, and that knocked an awful lot of "six-inch" product out of the running. The only options in the target size seemed to be a bunch of B-vent stuff for gas furnace flues and such. But a cap whose neck would fit inside the PVC but also shelter the junction sufficiently well might do, which allowed consideration of many more types of termination. A whole lot of searching and phonecalls finally landed on some suitable vent caps from R.E.Williams, which turned out to be rather flimsy and still needed a whole lot of modification and addition of bug screen before they'd really work. But light aluminum right-angle caps would eliminate the need to put anything else on top of the riser pipe, keeping the weight and complexity down. | |

Well, blow me down

|

|

|

They brought the typical

Minneapolis blower door

setup, and thought the front door would be the best place for it.

I thought using the side would allow testing how well *I'd* done on

sealing the front door itself, but we also needed to see if the side

door was tight too so it really didn't matter. They assembled the frame

and clamped the whole rig into the opening, making sure to route the

outdoor sensing hose off to the side away from the fan blast.

It was obligingly a little chilly outside that day, which would greatly help in hunting down leaks. They say they only need a delta of ten degrees to get decent reads on the infrared imager, and we had more like twenty to work with. | |

|

It took a bit of studying to learn this, but the flow sensor on the

Minneapolis fan is basically a pitot-tube ring mounted on the back

of the fan motor. Enough air has to be going *right* past that to

produce a readable pressure differential, and to help with that the

blower assembly comes with a set of insertable constriction rings

to narrow the flow path a calibrated amount. Trouble was, they didn't

have the smallest "Ring C" to put in even though we evidently needed it.

Apparently those have to be special-ordered from Energy Conservatory

to complete a setup usable on small, tight buildings. If you look at the

flow table for the Minneapolis model 3, ring B doesn't even start to

meaningfully register until something over 300 CFM, happily implying that

we were already under that.

But the Synergy fella had seen a C ring before and remembered about how big it was, and figured he might be able to hack something up that would at least give us a ballpark leakage figure. |

|

We got 336 CFM, which for my volume of just under 15,000 cubic feet would be 1.3 air changes per hour at about 50 pascals pressure difference [ACH50]. That's actually not too shabby, but part of why we were doing this was to find if there was more sealing work left to do. They said that smaller buildings were harder to achieve low ACH numbers on anyway, which makes sense as volume increases faster than envelope surface area. There are those who would argue that ACH50 is meaningless, but the air exchange rate is still very relevant when considering ventilation requirements. See this musing and related for more on the confusing alphabet soup swirling around this topic. |

At your service

Finally, a side storm

| When the Synergy guys had come by for the first blower-door attempt they also brought the storm door for the side, but got so ratholed in the air-leak testing they didn't have time to even consider installing it so they stashed it in the basement for some subsequent visit -- when they'd also come back with the right "C" ring for the blower. They had to order it. I didn't think about the storm door for a couple of days but then started getting curious about what was in the box and thought I should at least teach myself what comes with one of these. |

Return of the roofer

| With more of the major followup tasks getting completed, I really wanted to get the roof finished up. The extra panels had been on backorder for close to a month, and the poor guy's *better* bending brake had been sitting out in the weather the whole time. If I'd known it was going to take this long I would have brought it into the basement for him, but I thought he was coming back any day. |

Yet more water control

| A few afternoons later a guy quite unexpectedly showed up to install the gutters. Communication with the GC was starting to really fall off as the real end of the project drew near, as he hadn't mentioned this at all and it was good that I happened to be home. This was one guy in a box truck, no helpers, and I expected that he might want some amount of assistance from me. |

|

First job was to put the downspout assemblies together. He brought the fat, high-capacity 3 x 4 inch stuff, none of the weenie 2 x 3 most homes have. This wasn't seamless, it was sections that got zip-screwed together. The downspout mounting brackets were attached to the house at this point, which was a little interesting in the back as the strapping behind where he wanted to put the run wasn't quite in the right place. I had to remind him about how to work with the air-gap rainscreen. Perhaps I should have shown him one of my strapping pictures so he could see the actual path of wood he was trying to find. |

|

The set for the back would obviously be very long, and would go onto the house as a single unit. |

|

The assembled piece for the rear headed off through the yard. |

|

A ladders' eye view of the installation, before everything was buttoned down. Both here on the back and in the front it turned out that the roof panels were going to deliver water just about perfectly into the gutters. Here on the shed the panel line continued to just barely above the lip of the gutter, which might make eventual snow shedding easier; the angle was steeper on the front but that was fine as water might be rolling a little faster down the front and it would zip right into the middle of that gutter. |

|

Yes, there is a very slight dip at the far corner of the overhang,

probably from that warped plywood and the framing piece that had to

be wrestled into place over there. That actually helped establish

proper pitch on the gutter as it got over to that point, so it's all

good. You'd never notice that unless you were looking for it.

Nothing fancier than a small bullet level was needed to establish overall

pitch toward the downspouts; I had envisioned complex machinations with

a water-tube level held up at either end but it's much easier than that.

What isn't shown is that both runs of gutters got leaf-guard screen covers, I think one of several different types made by Englert although I can't find the specific type on their website. There's a shot of it later on, when I pulled some of it to experiment with different types of gutter-guard. | |

|

Sandy actually didn't drop that much rain overall, but she brought far and

away the highest winds I've ever seen around here and it was pretty

downright scary for a while with everything whipping around. Fortunately

all the trees remained upright and didn't fall on my nice new roof.

Again, the downside of all that complex structure up there is that in

the event of damage, it's far more of a bitch to fix than generic to-code

construction.

Part of my storm prep had also been to compact that remaining pile of polyiso foam pieces in the backyard and tie the whole pile down so pieces wouldn't start blowing away. They would have gone everywhere if I hadn't done that. I was really glad I'd gotten the storm door onto the side, too. Sandy came straight from the east for most of the time, and that whole side of the house was *covered* with crap afterward as the overhangs were rendered largely irrelevant. The nice well-sealed storm door bore the brunt of the sideways wind and rain and kept the main door completely dry, which would have been a soaking mess otherwise. It also let me spot a couple of small water leaks in the storm-door system that got caulked up later.

|

|

At this point I figured all the random drainage issues had been fixed,

even if the supporting structure underneath wasn't perfect. *IF* the

various re-sealing along the ridgeline stayed intact, the installation

of Tri-flex [and/or that lame substitute tarpaper on the shed] was all

good under the roof panels and over the drip-edge, the ridge cap not

leaving any water paths farther in, and all the layers of

Grace underneath correctly patched and sealed, I should be in good shape

for the foreseeable future.

It just still mildly sucked knowing there were several *preventable* issues

under there that I'd just have to live with. I would watch the siding for

any signs of mis-routed water, and a peek up inside the overhang soffit

every so often couldn't hurt now that I knew how to zip it open.

Ironically, contracting companies spout lots of stuff about "durable structures", and then only offer a one-year warranty on their work. Knowing what I know now, that speaks volumes. The only remaining minor problem was the fact that water falling down that very long downspout in the back was *loud*, and right outside where I sleep. I began thinking that water with that much velocity could eventually start eroding the downspout from the inside, and started wondering what I could do about that. Reroute the whole thing with an extra bend or two? A longer-radius elbow at the bottom? A bit of searching on what parts might help turned up something at Gutterworks called a downspout silencer, which seemed like an easy first thing to try. The picture there didn't show every detail but the more I thought about it, buying something like this seemed silly when I could probably just construct my own equivalent. |

|

A zero-fastener approach was probably best, relying on little bent tabs to retain the sponge piece. |

HVAC integration

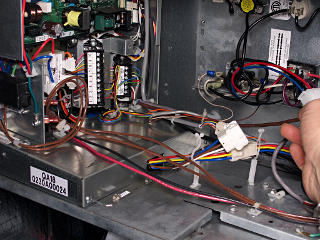

Over time I had finally clarified what functions and cross-connections

I wanted to add to the HVAC system, and had determined which ones were

feasible and which weren't. I needed a few external components and

accessible interconnect points, and figured it would be easiest to tie it

all together in one place. In particular, I needed to implement all of

|

|

The AHU end of all this also worked out nicely, with a single multiconductor cable breaking out near the terminal blocks and the heater relay. My leads to the heater relay [actually a "therm-o-disc" time-delay contactor] pushed right onto the double-tab quick connects and everything else found its way to a terminal block. Exact connections were important, as each function's terminal pair has what I arbitrarily named an "R" side and a "C" side from the 24V power supply and mixing them up would risk blowing a little not-easy-to-access fuse on the control board. Here's a wiring diagram of the whole setup, partially for my own reference but also instructive to anyone else looking to enhance the functionality of this particular air handler or work around its deficiencies. I even tried to make the wire colors vaguely match those found in typical thermostat connections. |

_H* 121228