Heat pumps are great technology, until they aren't, when something goes

wrong.

Then it can turn into a deep dive into technical diagnosis and frustrating

guesswork, often chasing subtle and hard-to-find problems.

The Daikin was pretty solid for six years after installation, other than the

waterlogged thermistor problem.

Then, just heading into the next heating season, one October day I noticed

that it seemed to be running for a really long time and not managing to make

much useful heat.

The superficial "diagnostics" I could get from the controller told me that

the overall output from the indoor coil was only 80 degrees or so, not up

to the usual 105 or 110 where it usually runs.

That might have eventually gotten the house somewhat warmer, but at the

expense of how much time?

Clearly, something wasn't right.

Heat pumps are great technology, until they aren't, when something goes

wrong.

Then it can turn into a deep dive into technical diagnosis and frustrating

guesswork, often chasing subtle and hard-to-find problems.

The Daikin was pretty solid for six years after installation, other than the

waterlogged thermistor problem.

Then, just heading into the next heating season, one October day I noticed

that it seemed to be running for a really long time and not managing to make

much useful heat.

The superficial "diagnostics" I could get from the controller told me that

the overall output from the indoor coil was only 80 degrees or so, not up

to the usual 105 or 110 where it usually runs.

That might have eventually gotten the house somewhat warmer, but at the

expense of how much time?

Clearly, something wasn't right.

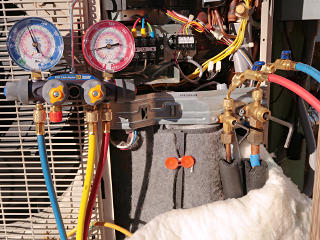

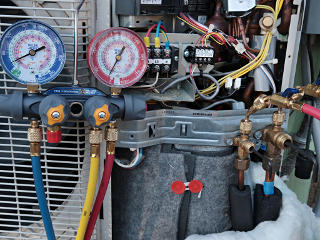

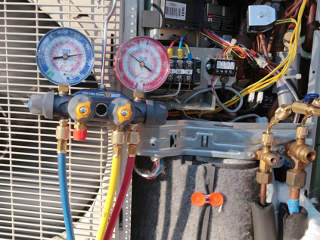

The "service mode" on the control panel also showed the outdoor evaporation temperature wandering around at a fairly ridiculous low level, like -20F in maybe a 40 degree day. Normally the system runs the outdoor coil about 10 - 15 degrees under ambient, which is enough to pick up heat from the outside air and bring it inside. This is a little nonintuitively puzzling -- if the outdoor coil is so much colder than the air around it, why wouldn't it be picking up *plenty* of heat to transfer in?

Well, the properties of refrigerants aren't that simple, and the numbers I was reading were actually quite misleading. To transfer heat efficiently, refrigerant has to change state evenly across the entire area of an exchange device, aka a coil with fins on it. If liquid refrigerant flow is low and it tries to expand into a given volume of piping, it can all flash to gas immediately and then spend the rest of the journey through the exchanger fairly uselessly at ambient temperature, picking up almost nothing. So it might get really cold early in the process, but there just isn't enough mass of it flowing to maintain that state-change process through the entire length of piping.

![Schrader caps off [with leftover dye] Schrader caps off [with leftover dye]](tn/288schrad-open.jpg)