|

|

| Series | Parallel |

Series/Parallel hybrid topology

More direct (and efficient) path to wheels

Electric-only drive capability -- "full hybrid"

Downsized components -- engine & motors can help push

MG1 and MG2 interchangeably power each other

"Closes the loop" for power transfer

Linked via the Power Split Device

PSD is a single planetary gearset -- nothing new here

Model T Ford

Almost any modern A/T is full of them

Essentially, it's a differential -- just lopsided!

Another view of the same thing

"Generator" and "Motor" really are misnomers

Both can perform either function

"Motor/generator" is the accurate term

Yes, the axles have their own differential too

(Just not shown in many of these diagrams)

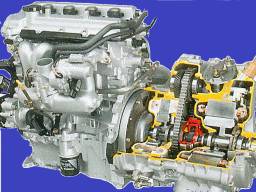

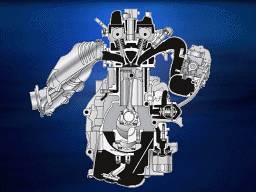

Toyota's trade-show transaxle cutaway

Two electric motor/generators

MG1 == "generator", charging, starter, and torque-balance

MG2 == "motor", traction and regen

Mnemonic: 2 is larger than 1

(And they're both smaller than the engine!)

Engine shaft through center

Connects to planet carrier (inner black line)

Runs a small fluid pump at far end

MGs run on sleeves around that

MG1 is sun gear

MG2 is ring and road (outer black lines)

...that's a little hard to see here -- there are

THREE concentric parts where the chain takes off

Engine torque splits 72% to wheels, 28% to MG1

NO mechanical shifting, except park

"Continuously variable" is done electrically

This tech stole the show!

Lacey, WA alternative fuel fair

A whole Classic transaxle to play with

He's holding the engine shaft / carrier

Final drive from ring multiplies torque

Chain take-off reduces side loading

The Prius has a "4.11 rear"

Engine shaft, sun gear, ring turn independently

Rotors are strongly magnetic!

Keep laptops, cards, etc away

This unit is *heavy*

As you might imagine, with all that iron inside

Toyota considers this a FRU

Simple and (hopefully) reliable

And yet there are complete overhaul instructions

Independents can maybe rebuild them?

Opportunities will be rare

MG2 slings a little oil

Maybe makes up for pump not turning?

Gen 2 rotors are smoother

Here's the 72/28% split again

Simplest graph of torque/RPM relationship

Read RPM (for all) down left side

Read road speed (for MG2 only) down right

MG2 RPM has direct correspondence with MPH

Useful engine (ICE) RPM 1000-5000, or OFF

Gears treated as levers/pivots

Hold back MG1, and the car moves

Just like sand under the spinning tire...

Two shopping carts and a broomstick?

It's all about balancing loads

Play with the models

Understand torque-transfer

Meet "Torquey the Muppet"

Rework of 1.5L Echo plant

This is good for 50+ MPG by itself

Closely matches ASE composite type 3

Many efficiency hacks...

Offset crank

Narrow bearing surfaces

Low-tension rings

5w30 or lower oil

Belt only drives primary water pump

Low friction in general (can turn with one hand!)

VVTi with Atkinson/Miller intake

Lower compression, higher expansion

Nominal 13:1 turns into 8:1 on intake

Extracts more net energy from gases

Significantly better FE, slightly less torque

Original Atkinson linkage changed piston stroke

see excellent animation at

http://keveney.com/Atkinson.html

Miller simplified w/ delayed intake close

Pushes a little mixture back into plenum

Compression tests *will* be lower...

Several operation modes/ranges

Variable intake, fixed exhaust

Range 4 yields high MPG!

Full retard during fuel-cut "warp stealth"

Internal EGR via valve overlap

No external plumbing to fool with

This is becoming typical in VVT systems

How to monitor valve timing?? Scantool lies

Chain cam drive

Direct bucket lifters

Adjustment rarely needed if ever

34 tooth CKP (2 missing)

3 tooth CMP (1 missing)

No scantool "CMP learn" needed

VVTi actuator driven by oil pressure

Control solenoid nudges spool valve back and forth

Vanes inside sprocket hub set relative cam angle

cam/crank timing discussion:

http://techno-fandom.org/~hobbit/cars/vvt/

ETCS (not just in Prius now)

1st gen repair: fix/adjust

manual describes TPS R&R

2nd gen repair: throw it away?!

Manual doesn't even get into it...

But it's the same $750 of serviceable parts!

TPS angle must be restored

There's apparently no auto-learn

But no IAC to fool with, either

Diagnostic: listen/feel the motor PWM

It actively fights you when it's working

Failsafe rest position via return springs

Two springs set a default 15% TPS, slightly open

Dual-wiper pot for redundancy-checking

VTA1 used as main input

Two PCV hoses

One above plate, one below

Coolant loop around throat

Clean/lube butterfly is useful service item

Can clean/service without disconnecting coolant lines

MAF only, no MAP or BARO

Air box has charcoal HC filter

Oil sump in intake is very common

Several theories on why -- PCV, blowback, ...

May also include fuel distillates

Oil overfill seems to exacerbate it

P3191 "engine does not start"? Look here

Especially in cold weather

Oil viscosity may be a factor

Throttle-butterfly edge crud could cause sticking

More 1st-gens having problems now

http://techno-fandom.org/~hobbit/cars/tb/

3.7 quarts does not mean 4 quarts

1/4 inch BELOW full mark is about right

Bladder inside metal gas tank

(US/CAN market only)

Reduces vapor volume and loss

Stiffer and hard to fill in cold weather

Gauge sender is off to side, parallel plumbing

Returnless fuel system

Single-speed pump & regulator (in tank)

Nominal pressure 48 psi

No rail pressure feedback (would have been nice)

EVAP tests include bladder leak detection

Tank air pulled to intake and tested by A/F sensor

More pix and teardown/discussion:

http://priuschat.com/forums/tech/30593-bladder.html

Next

Fuel system

Diagnostics

14 ohm saturation injectors

Easy injector-wire access at ECM

Fuel supply tube & fittings under cowl

Scantool pump activation

No FP fuse, and "C/OPN" relay is semi-buried

Best pump-power access is under driver's kick-panel

Test adapters are hard to find

Toyota says "purchase new fuel tube"

<Insert whiney "fuel systems WTF" rant here...>

1st gen: O2 sensors

And HCAC adsorber (see next slide)

2nd gen: Wideband A/F at B1S1

Differential output -- both sides 3.something volts

Current-based, can't really scope it

Some scantools confused about its "voltage"

Post-cat is normal O2

Sits low, somewhat vulnerable...

1st-gen special second cat

Vacuum-actuated valve

Closed for warmup

Open for HC purge later

Problem: it rusts and sticks

Esp. in the Salt Belt...

P1430, P1431

Can possibly lube and work it loose

But it requires frequent attention

Vacuum fitting still present in '04+

Not used in 2nd-gen but still on the manifold

Convenient vacuum-gauge takeoff!

Some throttle-body hoses visible here

Note front PCV wear pattern from air box

Heat storage and retrieval system

(US/CAN only, not JP/EU)

Hot coolant "put away" in insulated tank

Used to preheat head/cylinders at next startup

Three-way valve directs coolant flow

Preheat is reverse of normal flow into head

Warms right around combustion area, lowers emissions

Normal radiator and cabin heater

With the addition of an electric circulation pump

(Remember that "furnace" thing?)

Scantool-driven bleeding procedure

Hex bleed tap semi-hidden under LHS radiator brace

Vacuum dewar bottle

Holds about 3 liters

Frequent collision victim

Has one of three engine coolant drains

Fairly easy access past fender liner

But don't mangle it (or its clips)

Bug: wasted preheat

Pump-in happens on most power-ups

But what if you're not going anywhere?

Which sensor is which here?

The manual may mislead

Oil pressure: switch only

Pressure transducer would be a nice hack...

Coil-on-plug ignitors

Iridium plugs, 100K

Pull and anti-seize them well before then!

Hole for electric block heater

(see "heatgames" webpage for many details)

http://techno-fandom.org/~hobbit/cars/heatgames/

The inverter blocks easy access to here

The ... what? Is that a car part?

Look around the engine

Examine throttle area

Find sensors (or difficulty of access)

Find my block heater

(do NOT remove it -- thermal grease)

Find the fuel pump power

Under the LHS kick panel is easiest

This is what everyone asks about

Answer: "lasts the life of the car"

Charge management is the key

40% - 80% limits, seeks 60%

NiMH best present chemistry right now

High charge/discharge currents

But lithium is rapidly gaining ground

Note service-plug wiring!

Also contains battery ECU, relays, prechage resistor...

Hall-effect current-sensor donut is what I tapped

Tour de Sol hack-job charging experiment

... not particularly safe, but proof of concept

We don't need Toyota's magic charger

Prismatic modules

6 cells at 1.2V each = 7.2V

6 or 6.5 Amp-hours

Thermistor cavity

Classic pack: 6 Ah

38 modules == 273V

50A max charge/discharge

2nd-gen pack: 6.5 Ah

28 modules == 201V

100A max charge/discharge

Secondary cell interconnect for more current

Better cooling surfaces

Modules are all series-connected

String voltage monitored every 2 modules

ONE weak cell can ruin your day

Can read block voltages on scantool [~16V]

Real-life operational voltage is higher

273 --> 300, 201 --> 220

Compression rods hold the pack together

Otherwise, cells can easily bulge out

Warmed/cooled from cabin air

Batteries are happy at human "comfort zone" temps

Not sized for distance -- ~600Wh avail

Used for energy bouncepad, not the day's commute

1.5 or 2 miles max on "full" charge

Entire HV system is isolated

Battery, relays, wires, inverter, motors

Any chassis leak detected as a ground-fault

P3009 and system shutdown

Coaxial cable and shielded connectors

Penetration/damage likely to cause ground-fault

WARNING: Battery ECU sense leads still hot??

That ECU plug is orange for a reason

Components can be megger tested

But read the manual on how:

500V max, and all low-voltage electronics disconnected

Can track down ground-faults piece by piece

Do we know what we're looking at here?

Study the basics on motors and inverters

1st-gen electrical system

One of about 300 patents covering the car

Basic MG1, MG2, inverter shown here

Many lessons from industrial motor-control

Toyota had to design their own semis --

off-the-shelf wasn't good enough!

Analog position resolvers for commutation

Tamagawa-Seiki "singlsyn" type, quadrature output

Feedback loop includes the computer

Bridge PWM control sent straight from ECU

2nd-gen system has several improvements

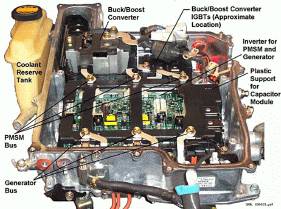

Buck/boost converter, steps up to 500V

Push motors faster, regulate charging

Higher efficiency motors

Updated IGBT power modules

Same position resolvers

Electric A/C with its own inverter

Variable speed, saves energy...

Run from HV battery, lots of power

Single bleed resistor drains all caps

And it's a funky one; see next slide

My clear cover for the "naked" exhibit

Not a whole lot to see up top

Major interconnects (200V, 500V, motors)

Capacitor module (separate cans in 1st-gen)

Green card is 64K bleed resistor assy

See "ginv" teardown webpage for in-depth detail

http://techno-fandom.org/~hobbit/cars/ginv/

Water-cooled, separate radiator section

Middle layer is a cold-plate

Pink tank is coolant reserve

Inverter can be shifted aside w/o draining

Some items accessible underneath

AirLift works well to refill if drained

Listen to the pump, look it up ...

Coolant drain in-line w/ transaxle hoses

Oak Ridge 890029.pdf shots

Capacitor module removed

PWM chop frequencies 5K and 10K

You can hear this while driving

Funky modulation schemes, based on speed

ECU sends 3 control leads + "gate"

Turned into six for 3-phase bridge

Gate disables control, such as for Neutral

Interlocks on covers/lid

And on 2nd-gen service plug, too

Easy enough to bypass...

DC/DC converter and A/C control

If both fail, might be that 30A fuse

Your tax dollars at work

Argonne/Oakridge papers are all public

MG1: ~12-15 kW, MG2: 50 kW

1st-gen slightly less

295 ft-lb @ 0-1200 RPM

~ 150 lbf tangential per pole at air gap -- times eight!

and that's *before* final reduction

Three-phase permanent-magnet synchronous AC

Eight poles, four electrical revs per rev

1st-gen motors are parallel-wound

2nd-gen motors are series-wound

Higher voltage, but less current

Motor windings can be a boost converter

Argonne/Oakridge *missed* that very important fact

We can demo this easily -- crank-n-spark

Waveform very similar to injector pulse

I have a webpage up about it...

http://techno-fandom.org/~hobbit/cars/boost-hack/

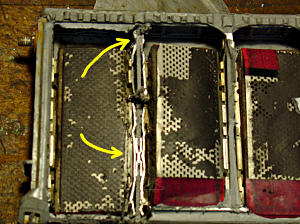

"Exploded" sub-pack

Pull spare inverter apart, ID parts

Electrical experiments

Play with 3-phase

Be the inverter -- can you keep up?