| Part 1: Overview; tires/brakes | |

| Part 2: Underhood | |

| Part 3: Headlights: the Big Schnoz | |

| Part 4: Inverter pump | |

| Part 5: Coolant testing | |

| ==> | Part 5b: Engine coolant |

| Part 6: Transaxle / driveline, references |

| This part was actually performed much later -- at somewhere over 150K on the clock, since initial testing showed a bit of life still left in the engine coolant. But now it was probably time to get it out of there -- just a simple drain and refill, without worrying about those frequently-upsold "flushes". As noted in the previous studies of coolant chemistry, a flush isn't needed if we're about to do a radical refresh on the additive chemistry anyway. |

|

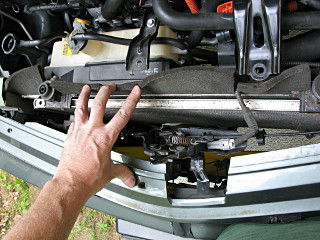

Once again, these items have to come out from around the front end and wheel, invariably taking a couple more of those little plastic push-pins with them ... |

|

Now it's relatively easy to push a short hose extension onto the drain so it won't drool coolant all over the lower support when opened. |

|

The radiator assembly is topped by these glued-in slabs of foam which are supposed to stand up straight and block airflow through the gap under the upper brace, but they evidently take so much wind blast that they have very little hope of remaining upright. And this is after I've had my top grille slot completely blocked for years now, even in summer. The vast majority of air comes in through the bottom grille anyway. |

|

|

|

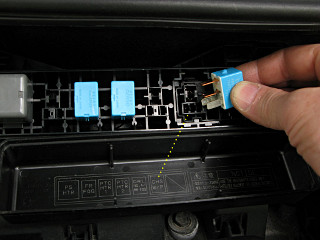

One tactic for trying to push fluid around in the system is to run the

storage-tank pump, which should at least help flush the plumbing around

the thermos. This is the pump that we hear run at startup and sometimes

at shutdown for a few seconds, and that also often gets really screechy

in cold weather. Thanks to Levi Smith and several others who logged their

own observations in a

Priuschat thread

about engine coolant change, we know that it's easy enough to bridge

the Coolant Heat Storage [CHS] relay output contacts and activate the pump

for brief bursts. The relay is in the little auxiliary panel mounted to

the middle of the cowl above the engine.

However, which way the pump pushes fluid depends on the position of a movable three-way valve in the midst of all that plumbing, that governs whether coolant is sent to or from the engine, thermos or the entire system. Of some note is the fact that this whole storage system doesn't exist on the non-US-market cars from '04 to '09, and Toyota has given up on this in favor of exhaust heat recapture in the third-generation Prius. By the time I start messing around with this, the sound of the pump pretty much indicates that the fluid level is already below it as it's just trying to grab air and spinning much faster than normal. It seems generally recommended [and supported by various scantools] to not run the pump continuously for any longer than about 30 seconds in general; of course if it's not moving fluid anymore then there's no point in running it at all. At a couple of points I notice a little steam coming off what's draining as the thermos empties, but what's coming out is not actually all that hot after an overnight sit. The service manuals do warn about potential scalds from the stored stuff, however. | |

|

In all I obtain a little over seven quarts out of the system, plus whatever soaked into the many paper towels I've sopped up various spills with. |

|

In general, the refilling process is sort of a slow pain in the ass similar

to the draining process. Add some coolant. Hit the CHS pump, which may

or may not pull the level lower. In the early stages I can hear the pump

working on some mix of air and fluid, taking "bites" at the coolant as

it gurgles its way into that part of the system. Gently squeeze the big

hoses [not hard enough to make fluid fountain out of the radiator neck!]

to try and push more bubbles out. Close the cap and bleeder and squeeze

the right and left hoses more briskly, both alternately and together, trying

to coerce more bubbles to the top of the system. Open up again and repeat.

The tiny clicking heard from the area of the thermostat is from the

jiggle valve,

a small deliberately designed penetration of the thermostat disc precisely

to allow coolant to flow back into the block and air to escape.

Eventually I get about a gallon and a half in and it's just not taking any more, so now it's time to start the engine and let it idle so the mechanical water pump helps push fluid around. The suggested "inspection mode" isn't needed for this, as idle is easy to achieve in normal operation. This also opens the three-way valve to the heater core, which has to have air purged out of it too. For a faster warmup, a little force-charging can put more load on the engine. The point is to let the engine come up to its normal 85 degrees C and start opening the thermostat. It is critical to monitor the engine temp at that point to make sure it STOPS rising -- I can do this with my temp gauge but a scantool or a Scangauge can show that too. The three-way valve also moves to the "whole system" configuration at some point after full running temp is reached, so in theory the water pump will be sending coolant through everything including the thermos at that point. The radiator fans may or may not come on during this -- if they do that means the engine has gotten quite a bit hotter than the opening temp of the thermostat. It also seems to help to run the cabin heat at "max hot" and vary the fan from high to off and back. While coolant generally goes through the heater core all the time and there's no on/off valve for flow thereof, there's an auxiliary electric pump that circulates between engine and heater-core when the engine isn't running [e.g. when you're back in Park] but cabin heat is demanded. And feeling lots of heat coming out of the vents helps confirm that the heater core has coolant going through it. Unfortunately this also tends to pull a lot of heat out of the engine block and close the thermostat again, so more running/idling may be needed. [After all, the heater core is basically a second radiator.] The bottom line is that just trying to cycle all possible parts of the system several times seems to be the best way to work the remaining air out and allow adding more small quantities of coolant.

Eventually the system seems to be as full as it's going to get, and the CHS pump sounds normal and clearly isn't chewing any more air pockets. As the system cools down its overall pressure will lower, so we want to also have some new coolant in the reserve tank for it to pull in. From here it's going to take a few normal warmup/cooldown drive cycles to purge any remaining air, including normal runs of the CHS pump at startup and shutdown, and eyeballing the radiator-neck level [but do not open with the system hot and under pressure!] and adding more tiny amounts of coolant as needed. Again, I refuse to use an "air lift" or other evacuation device on this due to concerns about collapsing thin-walled radiator tubing or damaging other parts of the system. Not that I've got shop air handy anyway, so that's sort of off the table regardless. From what I've seen when it's been done to Priuses anyway, there's still some significant air "burping" left to do no matter how much suction was pulled before letting fluid in. |